In the field of modern architecture, laminated glass has gradually become the material of choice for designers and architects due to its excellent performance and wide range of applications. It not only improves the safety and durability of the building, but also gives the building space higher aesthetic value and energy-saving benefits.

What is laminated glass?

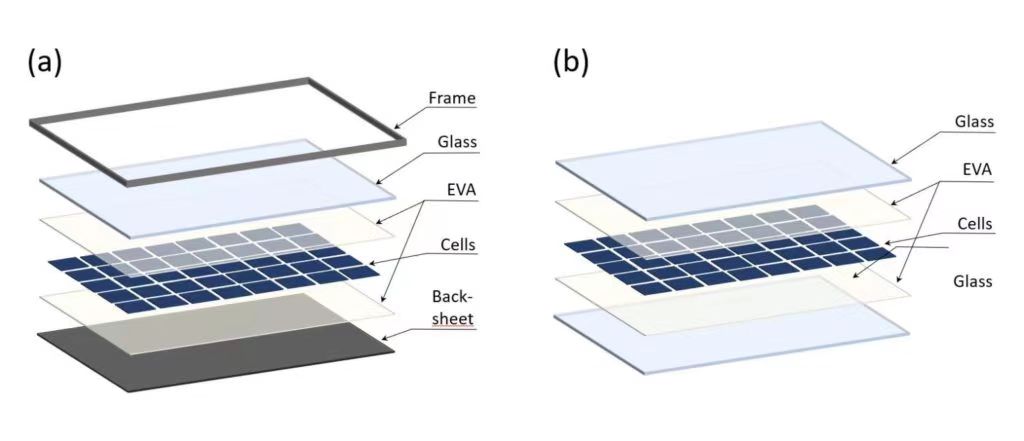

Laminated glass, also known as safety glass, is a composite material made by sandwiching one or more layers of organic polymer interlayer films between two or more pieces of glass and treated with high temperature and high pressure. This film is usually made of polymer materials such as PVB, SGP, EVA, PU, etc., and has excellent adhesion and toughness. Its basic structure is as follows:

Outer glass: As the outermost layer of laminated glass, tempered glass or float glass is usually used. It has good transparency and mechanical strength, ensuring basic visual transparency and impact resistance.

Intermediate film: The interlayer film is its core part. It not only plays the role of bonding two pieces of glass, but more importantly, it has the function of absorbing impact energy and preventing fragments from flying. When the glass is broken by external impact, the interlayer film can effectively stick to the broken glass fragments, prevent them from falling off and hurt people, and improve the safety of the building.

Inner glass: Similar to the outer glass, the inner glass can also be made of tempered glass or float glass, which together with the intermediate film form a stable laminated structure.

During the manufacturing process, clean and dry glass is first laminated with an interlayer film and then placed in an autoclave. Under high temperature (usually about 130°C) and high pressure (about 1.3MPa) environments, the interlayer film gradually melts and evenly spreads between the glass layers to form a strong bond. After cooling, laminated glass completes its transformation into high strength, high safety and versatility.

What are the characteristics and advantages of laminated glass?

With its unique structure and manufacturing process, laminated glass exhibits a series of outstanding properties, making it an ideal choice for modern architecture:

Sound insulation and noise reduction: PVB film has good sound insulation effect and can effectively reduce noise transmission. It is especially suitable for buildings near busy cities, airports, railways and other high-noise environments to create a quiet and comfortable living or working atmosphere indoors.

UV protection: PVB film has the ability to block ultraviolet rays, which can prevent indoor items from fading and aging due to long-term exposure to ultraviolet rays, while protecting people from the harm of ultraviolet radiation.

Thermal insulation and energy saving: The interlayer film in laminated glass can block the absorption of heat in the infrared spectrum, reduce heat transfer, help maintain indoor temperature stability, reduce energy consumption of air conditioning systems, and meet the energy saving needs of modern buildings. Part of the laminated glass has also added LOW-E film to further enhance its insulation effect.

Application fields

In the field of construction, laminated glass is widely used and in-depth. From the curtain walls of large commercial buildings to the doors and windows of family homes, from display cabinets in public places to the windshields of high-end cars, it plays an indispensable role, especially in public places that require high security protection, such as schools and hospitals. . Its excellent sound insulation and heat insulation properties also provide people with a more comfortable living environment.

Laminated glass also brings more creative space to architectural design. Designers can process it into various shapes, sizes and colors as needed to achieve personalized design effects. At the same time, the transparency, color, texture and other characteristics of the interlayer film also provide designers with more choices.

Touchthin Glass covers various types and specifications to meet the needs of different customers. At the same time, we also focus on after-sales service and provide customers with a full range of technical support and solutions. When you choose us, you’ll enjoy the perfect combination of quality and guarantee. If you are interested in our products, please feel free to contact us for more details.